History

In 1948, Compagnie Industrielle du Nord, better known by its brand name, Chantecler, creates Petrometalic, Inc. in Cambrai. At the time, its business was essentially geared towards gas station maintenance and fuel delivery.

Chantecler is sold to Total in 1956 and Petrometalic SA expands and broadens its expertise in fluid regulation. Soon its operations cover four primary sectors: petroleum, industrial pipes, hydraulic connectors, and manufacturing booster pumps, injection pumps, and inflatable packers (TP and industry).

During the 1960s, 1970s, and 1980s the family business builds its reputation in France and abroad, becoming known not only for its extensive experience with industrial piping and selling all types of connectors, but also for the quality of its water infusion rods and its packers (BIMBAR).

Around the year 2000, however, Petrometalic decides to focus its activities with the aim of becoming even more flexible and innovative. For this reason, in 1998 the company sells its maintenance division and its electronic petroleum laboratory to Schlumberger. Then, in 2003, the ATI department (industrial piping) is made into a subsidiary, becoming Petrometalic Fluid Systems. Around that time, the company starts developing geotechnical probes and pneumatic sampling pumps, which have numerous environmental applications (bore hole permeability tests, CO2 capture, soil remediation, etc.)

Today, Petrometalic employs some 40 people and exports to 50 countries, making the most of its rich experience, its ability to react quickly to new challenges, and its well-known technical skills. Over the years, Petrometalic’s primary objective has been to optimize the quality of its services for its clients.

Regarding fluid regulation, Petrometalic has been committed to producing and selling products finely adapted to their client’s needs for 50 years. With over 100 product categories, the company has a permanent stock worth 3 million Euros. If necessary, Petrometalic can also design products end-to-end, as is already the case for many booster pumps, cement pumps, infusion rods, packers, threaded sleeves and certain types of probes.

Activities

Petrometalic has separated its hydraulics activities into three departments:

Connectors & Accessories

The Connectors & Accessories department stocks and sells specialized industrial supplies for connections (hydraulic, pneumatic, chemical, and petroleum/fire related) and also installs flexible hoses (Parker).

Specific TP & Industry Activities

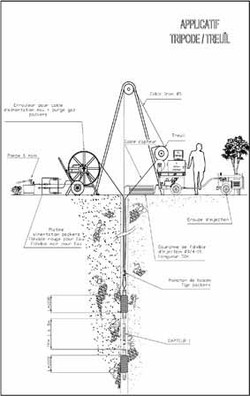

The Specific Activities department (TP and Industry) designs and sells inflatable packers (BIMBAR), test pumps, and booster pumps, as well as components for high- and very high-pressure fluid circulation.

Petroleum & Development

The Petroleum & Development department researches and designs specialized, custom-built equipment for resolving petroleum-related, hydraulic, and geotechnical problems, as well as numerous environmental applications (permeability tests, soil remediation, CO2 capture, etc.)

Sites

Petrometalic Cambrai

11, rue des Écluses de Selles

59400 Cambrai

Tél : +33 3 27 72 06 60

Fax : + 33 3 27 72 06 68

Petrometalic – headquarters

32 rue de l’Ermitage

78000 VERSAILLES

For more information, please refer to our Contact Us page.

Works

A few examples of our international work, including well-known construction sites that have used our products.

- Milan subway – Italy

Injection using 42 mm and 54 mm packers for strengthening and impermeability. - Lille Subway – France

Used 30 mm double packers in the sleeve tubes for injecting silicates. - The Channel Tunnel – France-United Kingdom

30 mm double packers used for permeability tests. PSC90 injection pump. - Yacyreta Dam – Paraguay

Panama River, between Argentina and Paraguay. Injection via 42mm, 54mm, and 72mm single and double packers, starting at the surface and underground injections for the impermeable curtain - Ataturk Dam – Turkey

Used 42mm and 54mm packers for the impermeable curtain - Saddam Dam – Irak

Injection via 54mm, 72mm, and 130mm inflatable packers for the impermeable curtain. - Béni Haroun Dam – Algeria

Under the direction of the Chinese Water Authority. 42mm and 54mm packers for strengthening. - Ertan Dam – China

Impermeable curtain using single 54mm and 102mm packers. - Xiolangdi Dam – China

Injections using 42mm and 54mm packers for the impermeable curtain. - Coal mines in Pingdignshan – China

Injection of cement with a SPC90 pump and 42mm packers. Water infusion with rods. - Tall Hosh and Medenki Dams – Syria

Impermeable curtain and water tests with double and single 54mm packers. - Evinos Dams – Greece

Strengthening with single and double 42mm packers. - Niagara Falls – United States

Use of 42mm and 72mm packers for injections. - Dul Hasti Dam – India

Kashmir – Use of 42mm and 72mm packers for strengthening and impermeable curtain. - Piedra Del Aquila Dam – Argentina

Strengthening and impermeability using 54mm packers. - Savana River – United States

Permeability tests and water sampling for analysis of ground water at Yucca Mountain (Oakridge National Laboratory), Hanford, Super Collider (Texas). - Vienna subway – Austria

Injection of Bentoninte, cement, and aluminate gel. - Temzouart Dam – Morocco

Agadir – Injection using 42mm packers for impermeable wall. - Bekme Dam – Irak

Impermeable curtain and strengthening with the help of 42mm and 54mm packers. - Tsing Ma Bridge – Hong Kong

Link to Chek Lap Kok Airport near Kowloon. Strengthening with the help of 42 mm packers. - Guandong Power Storage Project – China

Impermeable curtain using 42mm single packers - Lubin Copper Mines – Poland

Reinforcement of mine wells during digging with the help of 30mm and 42mm packers for injecting cement with our SPC90 cement pump. - Jubilee Line Extension – London, United Kingdom

30mm and 42mm packers for injections with sleeve tubes. - Arbre TGV Viaduct, Lille-Brussels

30mm and 42mm double packers for micropiles.

And many others…